The same accessories can be used to measure the spectra of coatings on metal surfaces such as protective or decorative polymer films on food and beverage cans. Very simple accessories using two flat mirrors can be used to obtain reflection spectra from flat surfaces. It is also very effective for carbon-filled polymers. This is a common approach for obtaining spectra of single crystals and from polished surfaces of minerals.

SPECULAR REFLECTION SOFTWARE

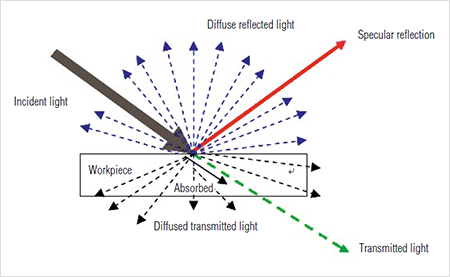

However, it can be converted into an absorbance spectrum by a mathematical process called the Kramers–Kronig transform which is provided in the software from instrument suppliers. The reflection spectrum from the surface of a continuous solid, such as a large crystal or a block of polymer, does not resemble an absorption spectrum, being determined by the refractive index according to the Fresnel equations. Reflection measurements can be conveniently divided into surface or specular reflection and diffuse reflection. The specular gloss can be safely included when comparing two identical materials but may be excluded when comparing two materials with significantly different gloss levels as long as the same measurement technique is used. The gloss port is located at an eight degree angle opposite the lens port and opens automatically when selected during the calibration routine on most software programs. The glossy reflectance – or specular gloss – is automatically removed when using a 45/0 instrument and can be removed from a diffuse/8 instrument by use of a specular gloss port. When these types of materials are measured for new shade formulation or when samples are measured behind a glass plate, it is important to exclude the glossy reflectance from the sample measurement. These materials include shiny paint chips, plastic panels, and magazine pages among others. Many materials used as standards for shade matching appear glossy when viewed from a particular angle.

The role of a colour measuring spectrophotometer is critical and one has to look into the design features and select a suitable instrument for textile application. To a normal observer, a high gloss specimen would appear to have more chroma and be a darker colour than an identically pigmented specimen with lower gloss or increased surface texture. Therefore, the appearance of the colour has been affected by the scatter of the specular light. However, in order to see the apparent colour of the sample, the observer must move their eye away from the specular and concentrate on examining the diffuse (scattered) reflectance from the sample.These necessary viewing conditions have led to standardized test methods such asASTM D 1729 ‘Standard Practice for Evaluation of Colour Differences of Opaque Materials’, where 0°/45° (or 45°/0°) (lighting/viewing) geometry, which avoids the specular, is recommended ( Hunter 1975). Specular reflection (light directed in an angle that is exactly opposite to the incident light or when the angle of incidence is equal to the angle of reflection) is generally less than 4–5% of the total and is perceived by an observer to be the ‘shininess’ or ‘glossiness’ of the sample. Gangakhedkar, in Colour Measurement, 2010 10.2.4 Colour versus appearance

Eventually, despite many attempts to improve the test apparatus and to standardize viewing conditions more closely, the method was dropped by the committee responsible for BS 3900 methods, being replaced, effectively, by the 85° specular reflection method of BS 3900: Part D5:1980 ( Fig. The technique gave reproducible results for the same observer but, inevitably, there were frequent differences of opinion as to whether a pattern was just visible or not. From about 1940 to 1980 the standard UK method, described in its final form in BS 3900: Part D3:1975 (withdrawn June 1983), was to assess the highest angle from the surface at which an image of a pattern of black and white bars, reflected in the surface, could be resolved. Visual methods might seem simpler and, therefore, more attractive. Results obtained by this method are sensitive to planarity of test specimens and to correct alignment of the glossmeter, but the technique can be used as a go/no-go method to exclude finishes showing significant sheen even if its value for exact measurement is doubtful. One method for assessing this so-called sheen effect is to measure specular reflection at a near-grazing angle, e.g. Specular reflection at low angles to the surface is the source of glare on table tops under bright light, and of stray light in optical instruments and it is often undesirable in interior decoration, where it shows up unevenness of walls and ceilings.

0 kommentar(er)

0 kommentar(er)